In today’s fast-paced manufacturing and production environments, ensuring high-quality products is essential for success. Manufacturers need reliable and efficient inspection methods to catch defects and inconsistencies early in the production process, preventing costly errors and rejections. Optical inspection instruments have emerged as valuable tools in the field of quality control, providing precise and non-destructive inspection capabilities. In this article, we will explore the importance of optical inspection instruments and how they can enhance quality control in various industries.

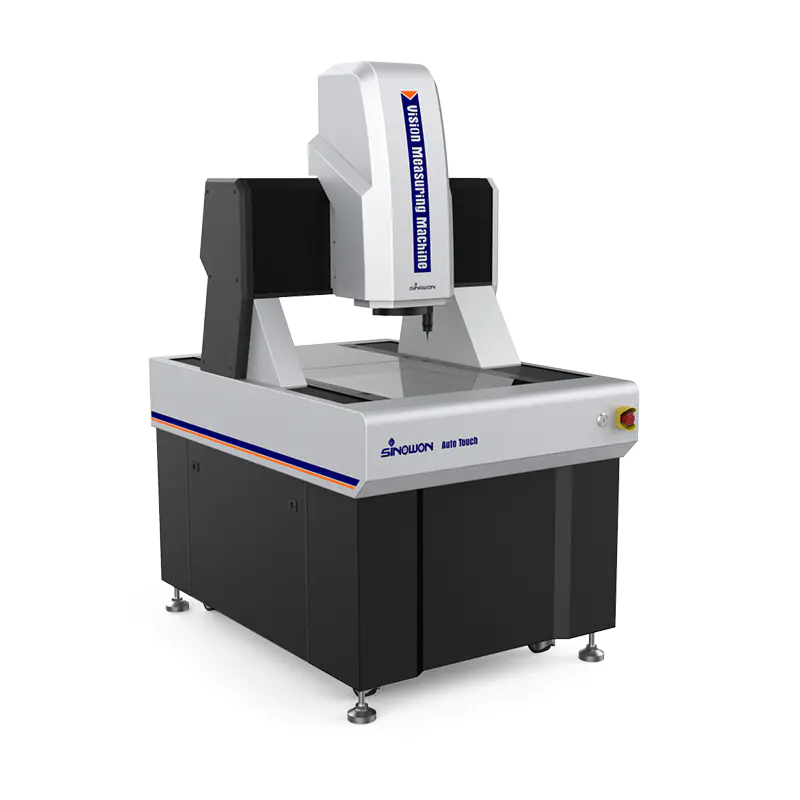

Optical inspection instruments refer to a range of devices that use light-based techniques for inspection and vision measurement systems manufacturers purposes. These instruments utilize the principles of optics to capture, process, and analyze data from the objects being inspected. They can be used to assess a wide range of products, including electronic components, automotive parts, medical devices, food and beverages, pharmaceuticals, and more.

One of the key advantages of optical inspection instruments is their ability to provide non-destructive testing. Unlike traditional methods that may require destructive testing or sampling, optical inspection instruments can inspect products without altering or damaging them. This non-destructive nature of optical inspection instruments allows for comprehensive and repetitive inspections without affecting the integrity or functionality of the inspected items.

Optical inspection instruments offer a variety of inspection techniques, including visual inspection, imaging, and measurement. Visual inspection involves the use of high-resolution cameras and powerful illumination sources to capture images of the object under inspection. These images can then be analyzed using specialized software to detect defects such as scratches, cracks, or surface imperfections. Imaging techniques, such as X-ray imaging or infrared imaging, can reveal internal structures or hidden features of objects that are not visible to the naked eye. Measurement techniques, such as laser scanning or profilometry, can provide precise dimensional measurements of objects, ensuring compliance with specifications and tolerances.

One of the most significant advantages of optical inspection instruments is their accuracy and repeatability. These instruments can capture and analyze data with high precision, detecting defects and inconsistencies at micron or sub-micron levels. This level of accuracy is critical in industries where small defects or deviations can have a significant impact on product performance and reliability. Optical inspection instruments can also operate at high speeds, allowing for rapid and efficient inspection of large volumes of products, thereby reducing inspection time and increasing production throughput.

Another key benefit of optical inspection instruments is their versatility. They can be adapted for use in various industries and applications, making them highly flexible tools for quality control. For example, in the electronics industry, optical inspection instruments can be used to inspect printed circuit boards (PCBs) for solder joint quality, component placement accuracy, and other defects. In the automotive industry, these instruments can inspect critical components such as engine parts, brake pads, and airbags for dimensional accuracy and surface integrity. In the food and beverage industry, optical inspection instruments can detect contaminants in food products, such as foreign objects or spoilage, ensuring food safety and quality. In the pharmaceutical industry, these instruments can inspect pharmaceutical packaging for proper labeling, sealing, and product integrity. The versatility of optical inspection instruments makes them indispensable tools in a wide range of quality control applications.

In addition to their accuracy, repeatability, and versatility, optical inspection instruments also offer other advantages, such as improved data management and traceability. Most modern optical inspection instruments are equipped with advanced software that can capture, store, and analyze inspection data, providing valuable insights for process improvement and quality assurance. Inspection data can be archived for traceability purposes, allowing manufacturers to track and trace the inspection results for each product, providing a robust quality management system.

In conclusion, optical inspection instruments have become indispensable tools in modern quality control practices. Their non-destructive nature, accuracy, repeatability, versatility