The word laser is used as a common name, but it is actually an acronym that stands for Light Amplification by Stimulated Emission of Radiation. The highly concentrated beam of light it produces can quickly apply energy even to a minute area. It can be easily controlled by mirrors and lenses and essentially as light. It can travel at the highest speed possible, can travel in a straight line in an empty space and can transmit information.

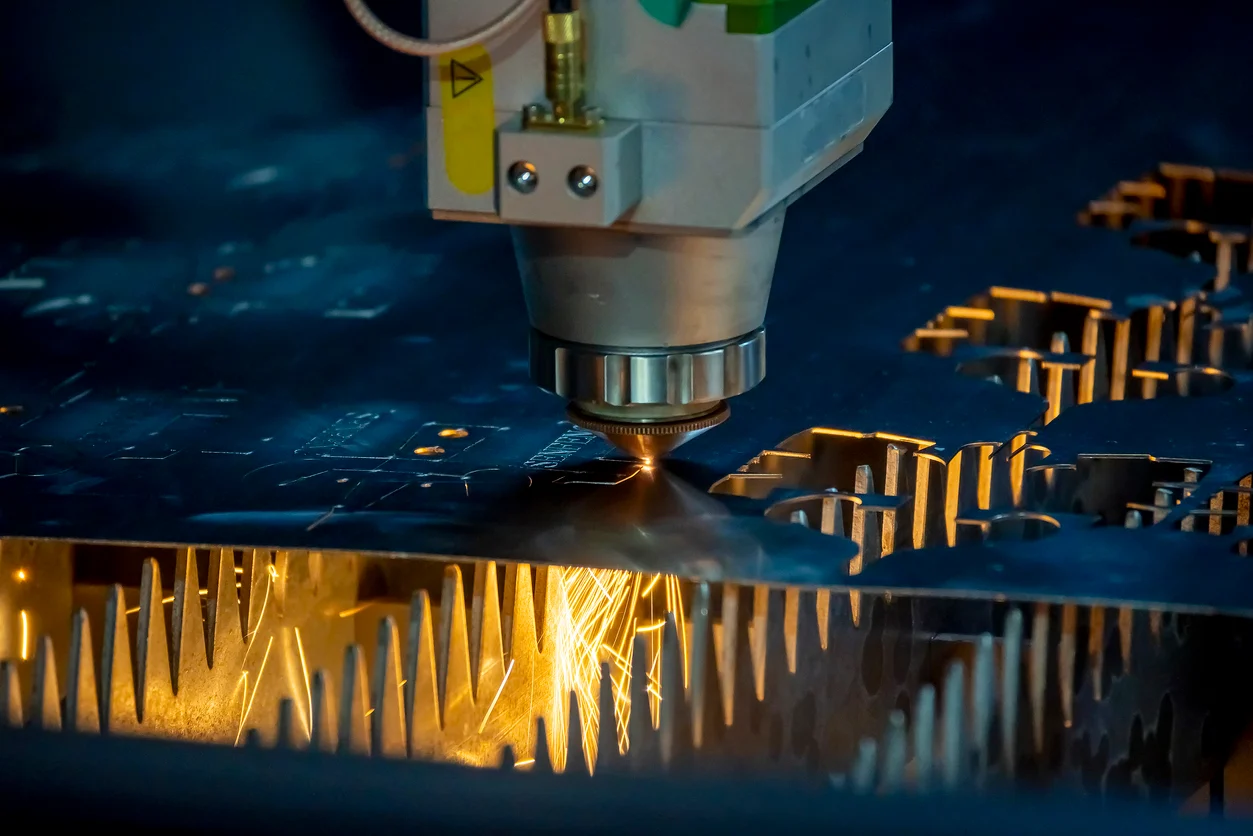

With these properties of Fiber Laser Parts Manufacturer, laser has found numerous uses; among them is in cutting. A laser cutter works by focusing the huge amount of energy it produces on a small area (even microscopic). The constant beam of light that hits the area causes it to melt or evaporate. A cut is generated by moving the object being cut or by moving the laser beam across the surface.

As a tool in cutting, a laser cutting machine has several applications. Some of its well-known applications are in medicine as a surgical tool, in craft-making and lithography as an etching tool, in garment industry as fabric cutter and in metal fabrication as welding and cutting tool.

Laser cutting of metals is laser?s most common and most beneficial industrial application. By means of a laser cutting machine, metals with complex profiles and contours can be easily and seamlessly cut. Its high quality cutting capability and fast cutting speeds eliminate further processing of metals reduces the production cost and improve productivity of certain companies using the technology.

The advancements in laser cutting machines, which includes enhancement of the beam quality, laser power, ease of use and operation and material, made it possible for a laser cutting machine to cut metals with multi-dimensions and tubular profiles. Highly advanced laser-cutting machines with this capability are quite helpful in the automotive industry.

Among the laser cutting machines used in cutting metals are flying-optic lasers, hybrid lasers, punch-laser machines, pivot-beam lasers and pulsed lasers.

Flying-optic laser cutting machines have high cutting speeds yet they are less expensive because of their fixed X and Y axis table. They are able to move over the material being cut in two dimensions. A more efficient and powerful pivot-beam laser on the other has X axis-travel capability.

Punch-laser machines are high power lasers that can cut metals with up to 3,500 watts. They perform several tasks including punching, marking, contouring and bending. They are mostly used to cut outer part and intricate inner contours. Pulsed laser machines on the other hand produce high power output for short period. They are ideal for piercing because of their ability to produce high power output in a short time.